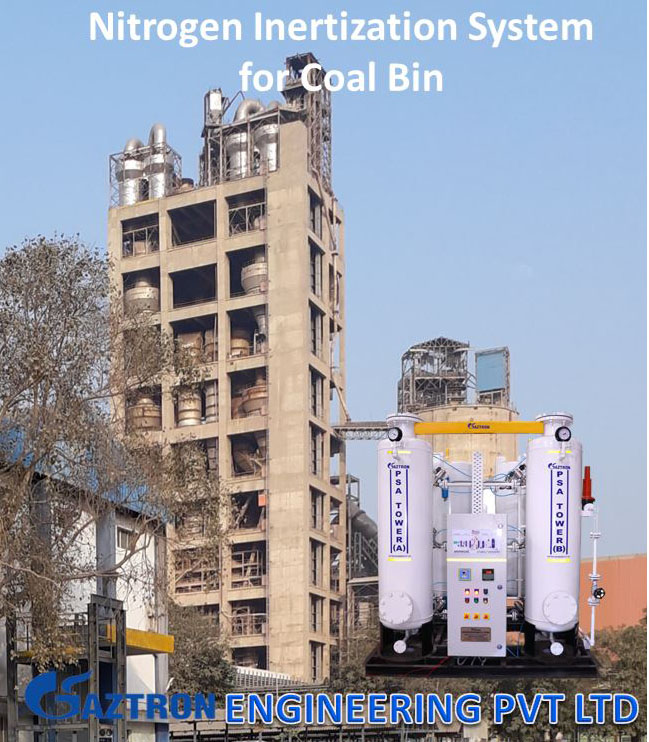

As a Basic Principal, Combustion is a high temperature exothermic redox chemical reaction between a fuel and an oxidant, it means oxygen, fuel and a heat is required to Combustion. We also knows the limiting oxygen concentration, (LOC), also known as the minimum oxygen concentration, (MOC), is defined as the limiting concentration of oxygen below which combustion is not possible As per flammability diagram we may find limiting oxygen concentration for certain process. By limiting oxygen concentration we may control Combustion, by inerting the Nitrogen we can control limiting oxygen concentration which decreases the probability of combustion Above Principal is used for Designing Nitrogen Inertization System (Inertisation systems) Coal Mill, Silos & Bag Filters in the Cement Industry Gaztron Engineering Pvt Ltd Designer, manufacturrs and Suppliers for full Nitrogen Inertization System consist of following Item:

Application of Nitrogen inertisation / inertisation system

- Nitrogen inertisation / inertisation system for Cement Plants

- Nitrogen inertisation / inertisation system for Silos

- Nitrogen inertisation / inertisation system for Bag Filter

- Nitrogen inertisation / inertisation system for Boiler

- Nitrogen inertisation / inertisation system for Bag Filter

Technical Specification of Nitrogen inertisation / inertisation system

- Nitrogen Gas Generator with Nitrogen Flow of 40 Nm3/hr to 500 Nm3/hr

- Nitrogen Purity 99 % to 99.9%

- Nitrogen Storage Tank 10 M3 to 50 M3

- Nitrogen Gas Booster up to 35 Kg/cm2

- High Pressure Nitrogen Storage Tank 10 M3 to 50 M3

- Nitrogen Pressure Reducing System as per Design

- Nitrogen Purging System with Nozzle and other Accessories

Scope of Services & Engineering Design of Nitrogen inertisation / inertisation system

- Basic Study of Customer System

- Data Collection of Installed System

- Calculation of Nitrogen Inertisation System

- Design the Total Nitrogen System based on Study

- Based on Design System Prepare Detail of Civil, electrical and Instrumentation System

- Supervision of System Installation

Scope of Supply & Major Equipments of Nitrogen inertisation / inertisation system

- Air Compressor

- Air Receiver

- Multi Stage Filtration System

- PSA unit - twin PSA tower filled by CMS with Change Over Valve

- Surge Vessel

- Electrical Control Panel with PLC

- Back Pressure Control System

- Vent Valve

- Oxygen Analyser

- Low Pressure Nitrogen Storage Tank

- Nitrogen Booster

- High Pressure Nitrogen Storage Tank

- Nitrogen Pressure Reducing Station

- Fully Automatic Control System with PLC for Nitrogen Purging

- Nitrogen Purging Station for each System

Erection and Commissioning of Nitrogen inertisation / inertisation system

- Erection of Total System

- Erection of Electrical , Mechanical and Automation system

- Commissioning system

- Synchronization of Nitrogen inertisation / inertisation system with Customer system

Online chat

Online chat

Online chat

Online chat