×Close Menu

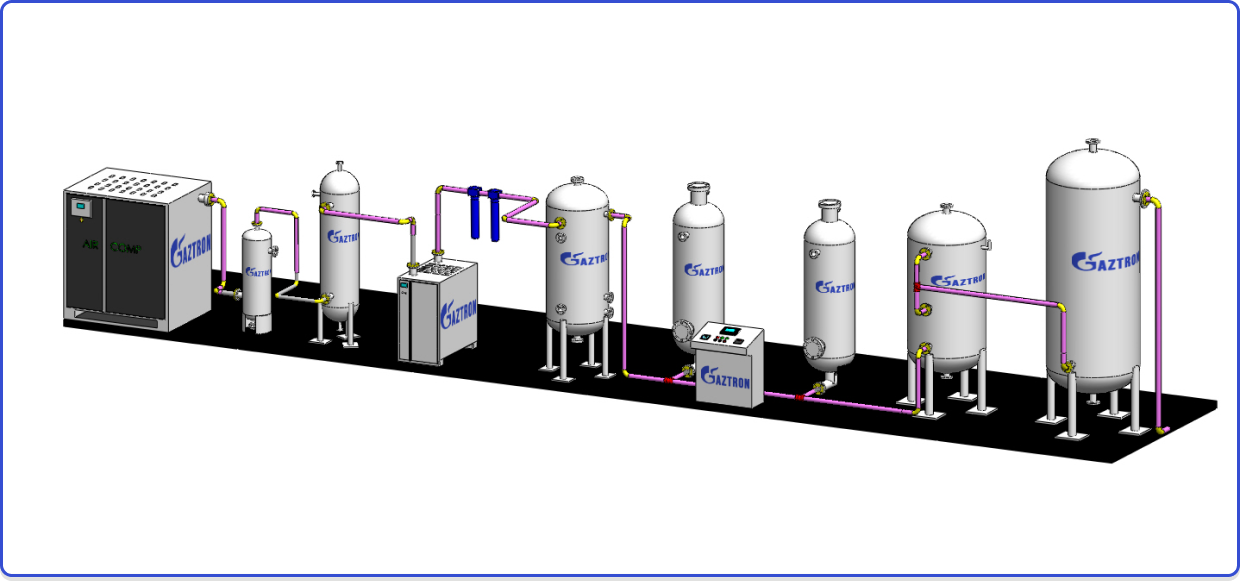

Nitrogen Plant →

- Nitrogen Gas Generator (CU-DX Model)

- Nitrogen Gas Generator (DX Model)

- Nitrogen Inertization for Coal & Cement Mill

- Nitrogen Blanketing For Storage Tanks

- Nitrogen for Food Packaging Industry

- PSA Nitrogen Gas Generator

- Gaztron's Membrane Type Nitrogen Gas Generator

- PSA Nitrogen Gas Generator for Pharmaceutical Industry

- Gaztron’s PSA Nitrogen Gas Generator for Automotive Industry

- Gaztron Technical Excellence ASME U Stamp-Certified Pressure Vessel Equipment Manufacturing